Intelligent Maintenance Management System

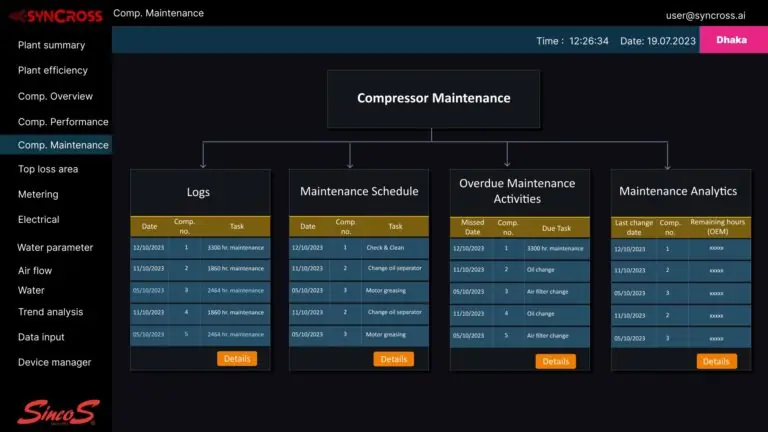

Intelligent Maintenance Management System (IMMS) is designed to optimize maintenance activities and improve equipment reliability in industrial settings. IMMS leverages advanced technologies like predictive analytics to monitor equipment condition, detect potential failures, and schedule maintenance activities proactively.By analyzing real-time data from sensors and equipment, IMMS can predict when maintenance is needed, identify the root causes of equipment issues, and recommend optimal maintenance strategies to minimize downtime and maximize asset lifespan.

Are you Facing Challenges?

- Raising Maintenance expenses

- Health and safety issues

- Prolonged shutdown of operations

- Manual work management

- Implementing maintenance strategy

- Equipment tracking and documentation

Our Solutions on Intelligent Maintenance Management System

Implement inventory tracking and analytics to optimize spare parts inventory and minimize stockouts.

Remotely monitor equipment performance, reducing manual inspections in hazardous environments.

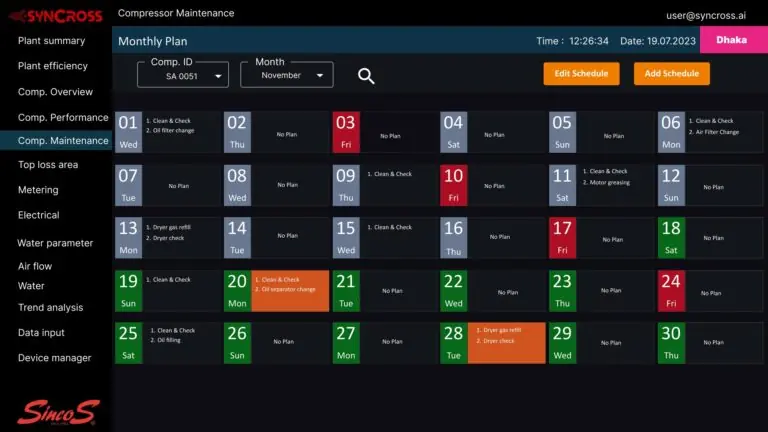

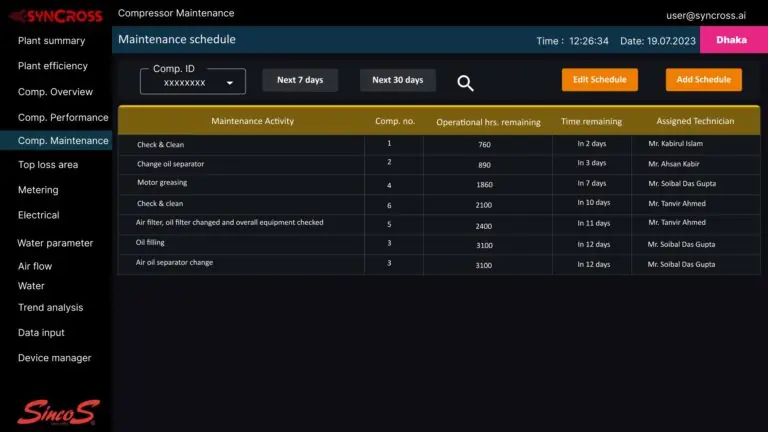

Ensure timely maintenance schedules, reducing the risk of prolonged shutdowns.

Utilize real-time sensor data for optimized maintenance scheduling and reduced expenses.

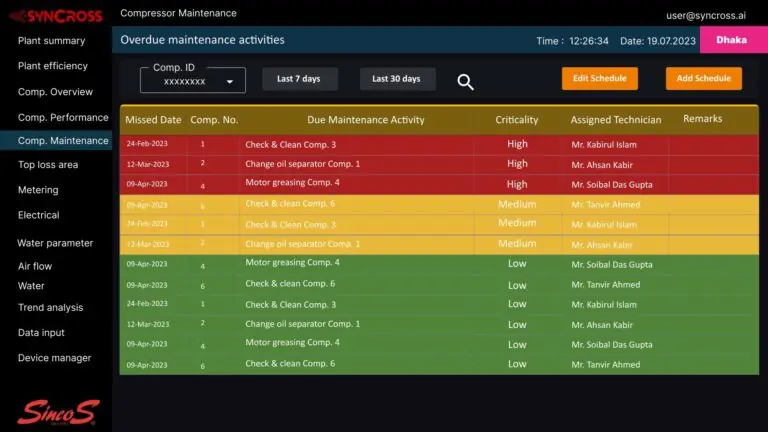

Proactively identify safety hazards or equipment failures for preventive measures and worker safety.

Track maintenance KPIs for continuous improvement of maintenance strategies and processes..

Implement collaborative platforms for real-time communication and coordination between maintenance teams.

Digitize maintenance documentation for easy access and reduced paperwork.

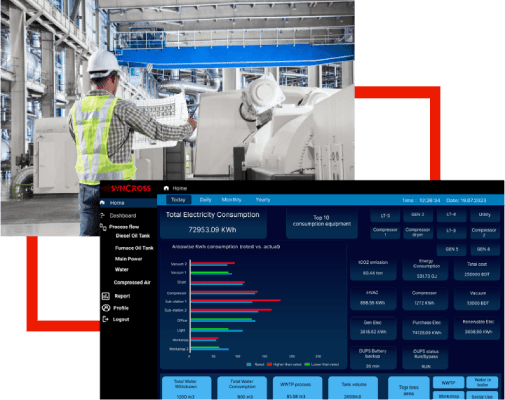

IMMS Dashboard