Production Enhancement System

The Syncross Production Enhancement System is tailored for the garments industry, offering cutting-edge tools to optimize manufacturing operations and boost efficiency. With real-time tracking of production processes, drag-and-drop workflow planning, and worker performance insights, it ensures seamless management of apparel production. Key features include delivery time monitoring, comprehensive production reports, and user role management, alongside a Quality Control Portal for real-time inspections and a Technical Helper Portal for instant issue resolution. Designed specifically for the garments industry, Syncross helps reduce wastage, improve timelines, and enhance productivity, making it the perfect solution for achieving operational excellence in apparel manufacturing.

Are you Facing Challenges?

- Inefficient data management for equipment, materials, and personnel.

- Increasing production cost

- Quality control processes

- Optimization of workflows, downtime reduction, and operational streamlining difficulties

- Ineffective machinery maintenance impacting production

- Challenges in managing production data effectively

- Challenges in workers efficiency

Our Solutions on Production Enhancement System

SynCross enables rapid adjustments to production schedules and layouts with a drag-and-drop interface.

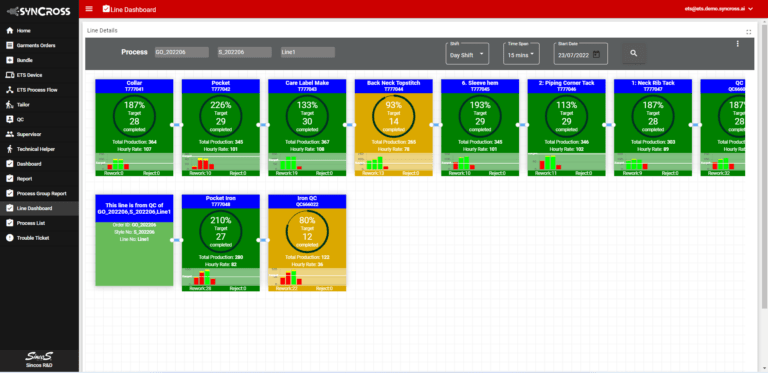

Real-time tracking of individual product batches or bundles provides visibility into their location, status, and progress.

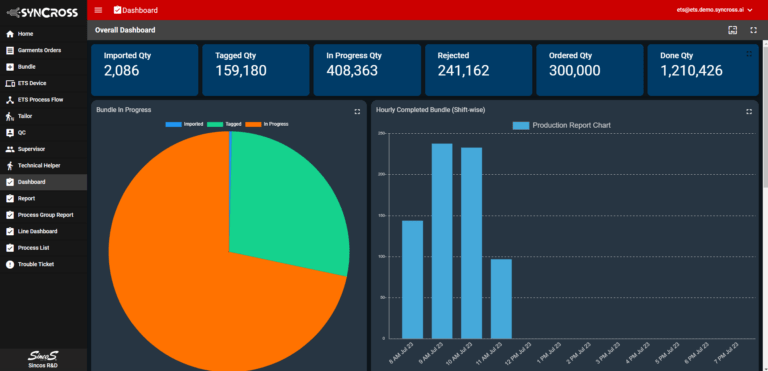

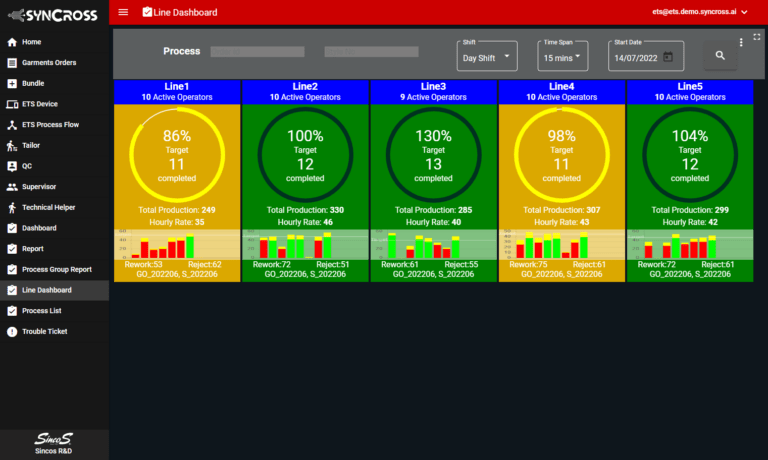

Stakeholders gain insights into crucial performance metrics like throughput, cycle times, and defect rates.

Generate real-time alerts and notifications based on predefined thresholds or conditions.

Track worker activity and performance metrics such as productivity, efficiency, and downtime.

SynCross analyses production data to identify trends, patterns, and anomalies, optimizing processes and improving efficiency.

AI-enabled simulations and optimization algorithms evaluate different production scenarios for cost, time, and resource utilization.

SynCross integrates with production planning and scheduling software for optimized schedules based on real-time data and demand forecasts.

PES Dashboard