Production Monitoring System

The Syncross Production Monitoring System is designed for manufacturing environments to collect, analyze, and visualize real-time data on production processes, equipment, and performance metrics. This system allows manufacturers to monitor key aspects of their operations, including machine uptime, downtime, throughput, cycle times, and product quality, ensuring enhanced visibility and control over production performance.

Are you Facing Challenges?

- Data silos for each manufacturing process

- Integration of disparate production systems

- Gaps between management and the manufacturing floor

- Complex workflows or distributed production facilities

- Maintaining Uptime

Our Solutions on Production Monitoring System

Implementation of robust security measures to protect sensitive production data and ensure data privacy, integrity, and confidentiality.

Seamless integration of data from disparate sources like equipment sensors, MES, ERP systems, and third-party applications.

Remote monitoring and control of production processes, equipment, and systems from anywhere with internet connectivity.

Real-time data from production equipment, processes, and sensors for up-to-date information on production performance and product quality.

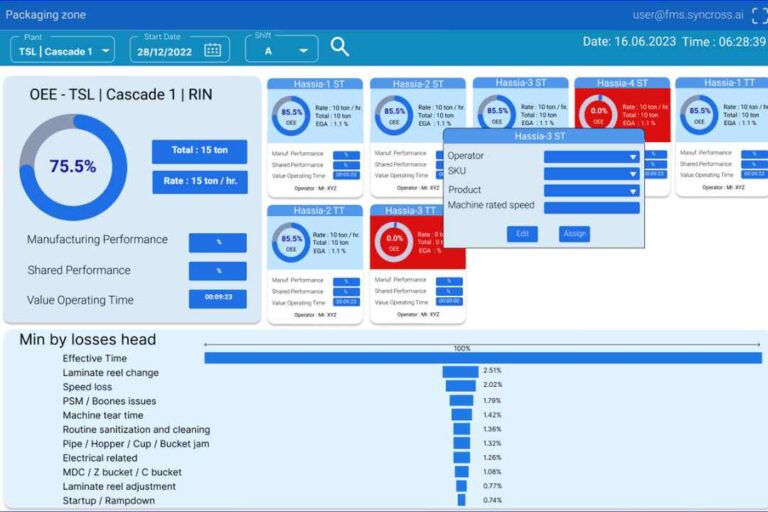

Identification of inefficiencies and optimization opportunities in production processes, equipment utilization, and resource allocation for continuous improvement.

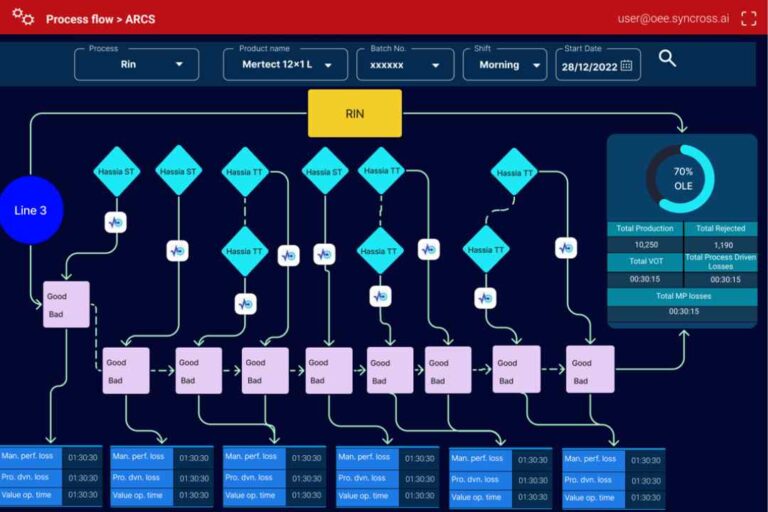

Visualization tools and customizable dashboards for monitoring KPIs, generating reports, and gaining insights into production performance.

PMS Dashboard