Smart Water Management

Smart water management through Syncross IIoT involves utilizing connected sensors, devices, and systems to monitor and optimize water usage in industrial settings. This includes tracking water consumption, detecting leaks or abnormalities in real time, and automating processes for more efficient water usage. By leveraging IIoT technology, industries can improve water conservation efforts, reduce costs, and ensure sustainable use of this critical resource.

Are you Facing Challenges?

- Implementing water conservation measures

- Monitoring and reporting water usage

- Identify energy consumption in water management

- Water quality maintenance

- Balancing water demand with supply

- Addressing wastewater disposal

- Regulatory compliance for water use and discharge

- Ensuring water resource sustainability

Our Solutions on Smart Water Management

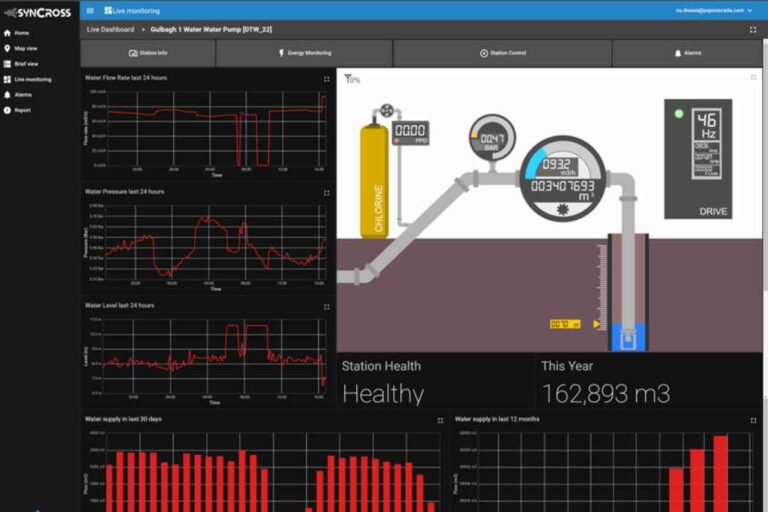

Supervisory Control and Data Acquisition (SCADA) system for automatic or semiautomatic pump control an monitoring.

Automatic mode, semi-automode or time based mode, controlled using touchscreen.

Automatic safety shut-off for under-voltage conditions Monitoring and data-logging of pump operation period.

Closed loop pump speed control (PID) using discharge line pressure as feedback (for preventing leaks)

Dry-run prevention using measurement signal from bore-well depth sensor.

Pump discharge control via variable frequency drive (VFD).

Interactive map with PTW production capacity data.

Summarized water quality data for all stations

Features for trend identification and forecasting

Gather data from an unlimited number of water stations, treatment plants (water and sewage), and individual household water meters.

Leverage zone-wise analytics to gain granular insights into water distribution networks, enabling informed decision making.

Integrate seamlessly with various data communication protocols, including MQTT, Opcua, DNP3, Modbus, RESTful APIs, and HTTP data push.

Additional Features

- Water quality monitoring: pH and conductivity

- Real-time Monitoring and data-logging of all sensor values including pump operation period, speed, pump power consumption,

alarms, well water level, pH, discharge flow rate, and total discharge volume. - Remote data transmission via cloud connectivity

- Remote data monitoring and logging

- Remote data reporting to anywhere in the world of all measured parameters

- Manual bypass mode with safety interlock for water depth and under-voltage conditions.

- Automatic alarm generation for excess discharge line pressure or insufficient flow rate.

- Live monitoring and data logging of pump power consumption

- Live monitoring and data logging of pump power consumption

- Password-protected access control for operator, technician, engineer, etc.

- Automatic tank level control and monitoring

- Optimized pump speed based on actual tank level and target pump level

- Recording of tank level data

- Electromagnetic flow meter at outlet of tank for consumption monitoring and data-logging

SWM Dashboard