Experience the power of innovation and intelligence.

Syncross-Industrial IoT Ecosystem is an innovative platform designed to revolutionize industrial operations by leveraging the power of the Internet of Things (IoT). The platform is fully developed by Sincos R&D team to serve as a comprehensive solution for businesses seeking to optimize their processes, enhance efficiency, and gain valuable insights into their operations.

On average, our clients have achieved...

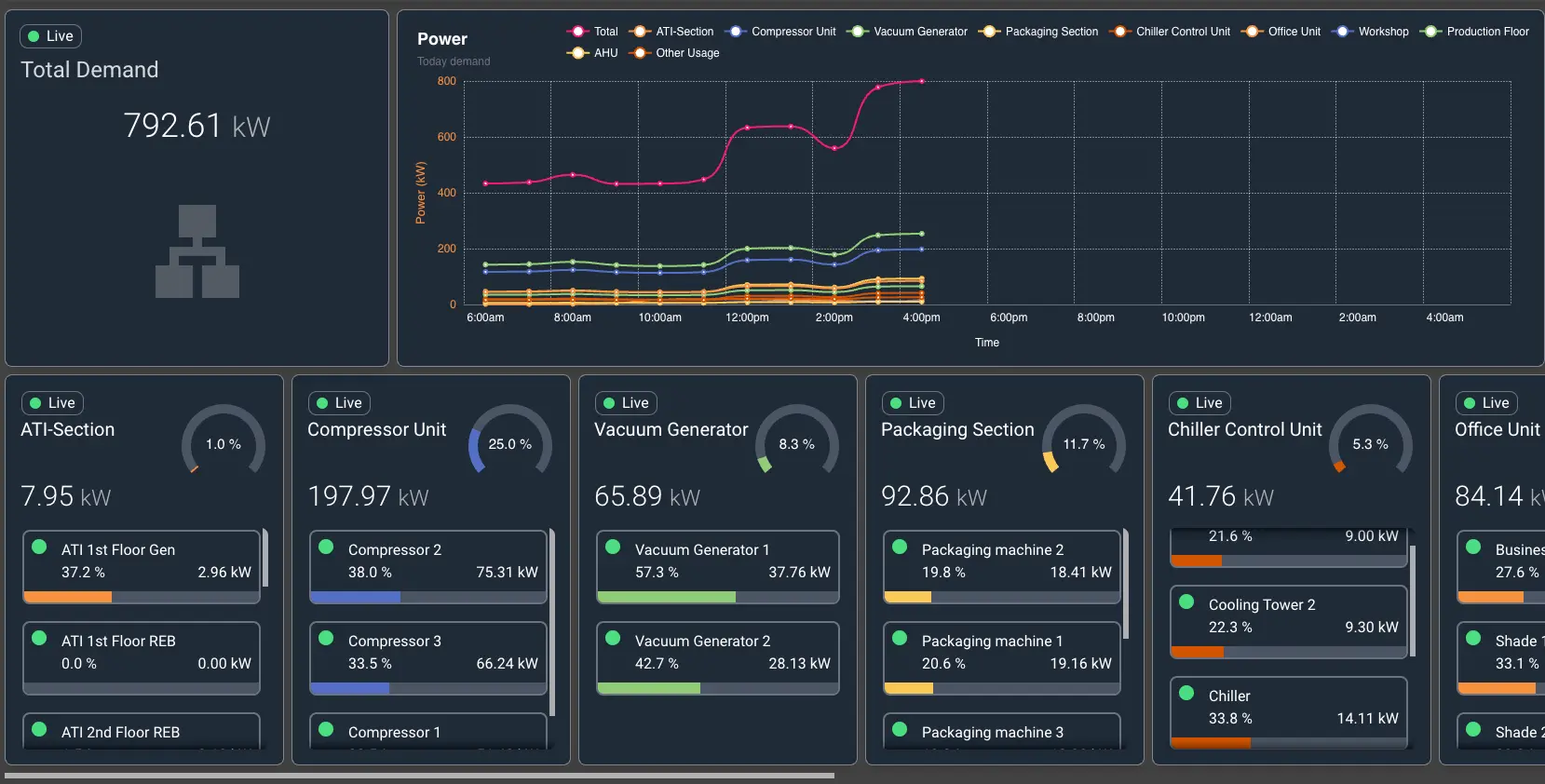

At Syncross, we bring intelligence to your industrial environment through real-time monitoring, seamless integration, and powerful data insights.

Track energy usage in real time across machines, departments, or entire plants. Syncross helps you identify inefficiencies, reduce energy costs, and meet sustainability goals with intelligent energy insights.

Control energy consumption across your facility

Syncross delivers advanced Utility Monitoring to help industries track and manage critical utilities like water, gas, steam, and compressed air in real-time. Our platform empowers you to optimize consumption, reduce waste, and improve operational sustainability.

Complete Visibility. Greater Control. Maximum Efficiency.

Syncross empowers industries to measure and improve Overall Equipment Effectiveness (OEE) with real-time data, smart analytics, and clear visibility into equipment performance. Gain deep insights into Availability, Performance, and Quality to unlock higher productivity and lower operational costs.

Maximize Equipment Performance. Minimize Downtime.

The Production Enhancement System in Syncross helps manufacturers improve productivity, streamline processes, and achieve consistent quality. By providing real-time visibility, intelligent analytics, and actionable insights, Syncross empowers industries to optimize every stage of their production cycle.

Boost Throughput. Minimize Waste. Achieve Operational Excellence.

The Syncross Intelligent Maintenance Management System (IMMS) transforms traditional maintenance into a smart, data-driven process. By combining real-time monitoring with intelligent scheduling and predictive insights, Syncross helps industries maintain equipment health, reduce unplanned downtime, and extend asset lifespan.

Prevent Failures. Extend Asset Life. Optimize Maintenance.

The Syncross Compressor Management System offers advanced monitoring and control of air compressor units to ensure efficient, uninterrupted, and cost-effective compressed air operations. From real-time tracking to preventive maintenance, Syncross enables industries to optimize compressor performance and reduce energy consumption.

Ensure Reliable Air Supply. Reduce Energy Waste. Improve Equipment Lifespan.

Stay connected to your facility, no matter where you are. Real time, Remote Monitoring-Anytime, anywhere in the world

Customize based on your requirements:

Deploy Syncross in the cloud for easy remote access or host it on-premise for full data ownership and control—whichever suits your IT and compliance needs.

Syncross easily connects with your existing PLCs, SCADA systems, ERP, and MES platforms—ensuring smooth data exchange and minimal setup time.

Connect directly to machines and PLCs using standard protocols (MODBUS, OPC UA, etc.) for faster data acquisition, processing, and visualization—right from the shop floor.

Your industrial data is protected with encrypted storage, scheduled backups, and high-availability cloud or on-premise deployment options to meet IT and compliance standards.

Get real-time alerts via SMS, email, or app for critical thresholds, faults, or abnormal conditions—allowing instant action before it impacts production.

Customizable hourly, daily, monthly, semi-annual, and annual reports in PDF or Excel format, designed for management, maintenance, and operations teams.

Define user roles and access levels to maintain security and data integrity across departments. From operators to executives, everyone gets the data that’s relevant to their job.

Centralize monitoring across multiple plants or branches, compare KPIs, and align performance goals at the corporate level.

Maintain a digital log of energy and performance data for ISO, LEED, or internal audits. Syncross simplifies reporting and documentation.

+1-408-355-8564

iot@syncross.ai

Please fill out the form to the right and a SynCross sales representative will be in touch soon.

Please enter your email address to download Syncross profile