Syncross is an advanced Industrial IoT (IIoT) platform developed by Sincosn Technologies Inc., designed to connect, monitor, and optimize industrial operations in real time. Built with the goal of driving smarter, data-driven industries, Syncross transforms traditional manufacturing and process environments into intelligent, connected ecosystems.

With seamless integration into existing industrial systems, Syncross provides businesses with live visibility into utilities, equipment, production lines, and energy usage—empowering decision-makers to reduce downtime, increase efficiency, and embrace predictive maintenance. Whether you’re operating a single facility or managing a global network of plants, Syncross delivers the insights and control needed to succeed in the era of Industry 4.0.

Syncross IIoT collects data from sensors on industrial equipment and systems, analyzing it to extract insights, detect patterns, and identify improvement opportunities

Using machine learning algorithms to predict equipment failures and maintenance needs before they occur, minimizing downtime and maximizing uptime.

Allowing operators to monitor and control industrial assets from anywhere, using webbased or mobile applications

Seamless integration with existing enterprise systems, such as PLC, SCADA, ERP and MES, to provide a holistic view of operations

Adaptable to different industries, processes, and environments, with the ability to scale up or down as needed.

Reports can be generated hourly, daily, weekly, monthly, half-yearly, or yearly, in multiple formats including pdf andf excel offering in- depth insights into industrial operation

Choose between storing data in the cloud platform, company-owned data hub, or Syncross data center based on preferences and requirements

Customizable solutions that can be tailored to meet the specific requirements of energy, utility, production, or any equipment and process needs

Syncross IIoT includes a failure prediction feature with alarm notifications, alerting users to potential equipment failures before they occur.

Syncross allows for realtime tracking of environmental factors and equipment conditions, facilitating proactive maintenance and optimizing operational efficiency

IoT devices includes sensors. SBC’s Gateways,PLC based Modules and conectors

Embedded into things in the IoT. Languages used include: Linux, C, Python, Qt

Devices connected to the internet and transfer data with Wired, Bluetooth, wifi, thread, 3G/4G/5G cellular network, LoRaWAN

Data from IoT devices is captured processed and stored. Server on premises or Cloud hosted e.g. AWS, Azure, GCP

Data from IoT devices is captured processed and stored

01

02

03

04

05

06

07

08

09

10

11

12

With a focus on delivering value and driving operational excellence, we work closely with our clients to understand their specific needs and challenges. Leveraging our expertise in sensor technology, data analytics, cloud computing, and machine learning, we develop customized IIoT solutions that optimize processes, enhance efficiency, and unlock new opportunities for growth

Our Industrial IoT solutions enhance production efficiency, reduce wastages, lower operational cost and help of real time monitoring and data driven approach

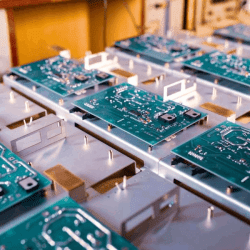

Our semiconductor and electronics solutions include pre-assembly insertion check, post-assembly verification, precision robot guidance, connector inspection and more.

Production efficiency, employees’ performance, real time equipment and process monitoring along with OEE in the textile and RMG manufacturing sector.

Managing routes, analyzing fuel consumption and tracking your expenditure in real-time will allow you to maximize productivity.

Water treatment plants are able to determine qualitative and quantitative knowledge about their asset and performance maturity, utility consumption and improve field operations by utilising real-time data.

Increasingly sophisticated devices, sensors and well-connected pipelines have revolutionized the operations of the oil and gas industry to ensure intelligent decisions are made and assets are managed in realtime

Syncross offers real-time plant status updates and automation in electricity generation. Analyzing data cuts maintenance costs and boosts eco-friendly power management

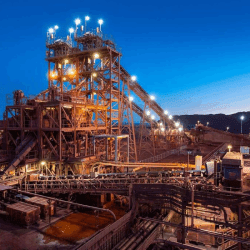

Discrete equipment and process brought under a unified platform: crushers, material handling systems, ball mills, ventilation, thickeners, concentrators, water pumps, ancillary systems.

+1-408-355-8564

iot@syncross.ai

Please fill out the form to the right and a SynCross sales representative will be in touch soon.

Please enter your email address to download Syncross profile