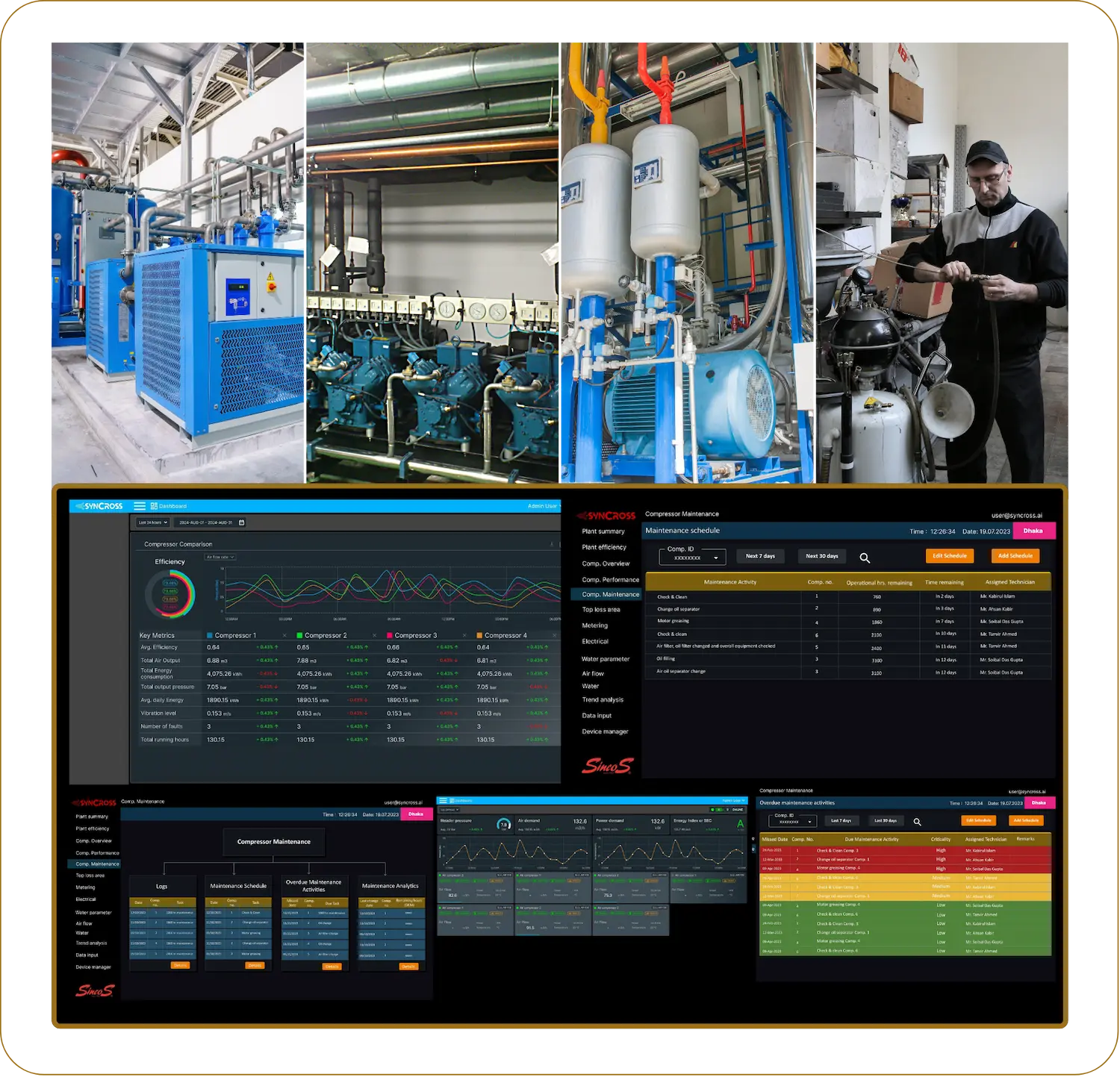

The Syncross Compressor Management System offers advanced monitoring and control of air compressor units to ensure efficient, uninterrupted, and cost-effective compressed air operations.

The Syncross Compressor Management System is an advanced Industrial IoT-based solution that enables real-time monitoring, control, and optimization of air compressors across your industrial facility. Designed for modern manufacturing, processing, and utility environments, our system helps reduce energy consumption, avoid costly downtimes, and extend compressor lifespan—delivering measurable ROI from day one.

Whether you operate a single compressor or manage a network of units across multiple locations, Syncross provides a centralized platform to keep your compressed air systems running at peak performance.

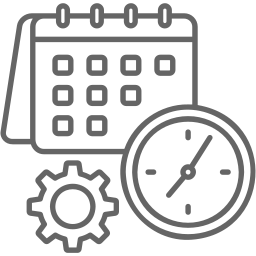

Track live data feed from each compressor with key parameters: pressure, temperature, power usage, and more.

Avoid unexpected breakdowns and reduce maintenance costs and schedule service based on actual equipment condition, not fixed interval

Analyze load cycles, idle time, and energy patterns and eliminate wasteful practices.

Track live data feed from each compressor with key parameters: pressure, temperature, power usage, and more.

Avoid unexpected breakdowns and reduce maintenance costs and schedule service based on actual equipment condition, not fixed interval

Analyze load cycles, idle time, and energy patterns and eliminate wasteful practices.

The Syncross Compressor Management System (CMS) is more than just a monitoring tool—it’s a complete solution that empowers your business to optimize operations, reduce costs, and extend the life of your compressor systems.

Automatically switch compressors ON/OFF based on demand patterns and optimize pressure settings and minimize no-load running.

Automatically store years of operational data in the cloud and Visualize trends in compressor performance, energy use, and maintenance history.

Track the cost of compressed air production per kWh or per cubic meter and Identify which units are most/least efficient. Calculate energy savings and return on investment in real-time.

Monitoring entire compressed air systems, including dryers, filters, and receivers, also detects air leaks and inefficient routing in the network.

Generate daily, weekly, or monthly, half yearly,yearly performance reports. Also create customizable templates for energy audits, downtime analysis, and maintenance logs.

Link alerts to work orders or maintenance ticket, schedule and track servicing activities through the dashboard.

+1-408-355-8564

iot@syncross.ai

Please fill out the form to the right and a SynCross sales representative will be in touch soon.

Please enter your email address to download Syncross profile